The Power to

Curb Carbon

XFC-Energy® Technology

We’ve Raised the Bar on Lower CO2 Emissions

Battery manufacturing is the highest contributor to CO2 emissions for the manufacturing of an EV. Now, Enevate provides the potential to substantially lower an EV’s carbon footprint at the start of life. Enevate utilizes a higher energy density material and an innovative, ultra-thin multi-layer design in its large format EV cells that meet the demanding requirements of EV applications. Enevate’s battery technology strives to provide EV and battery companies a process for taking measurable, cost-effective steps toward meeting carbon reduction and carbon neutrality requirements.

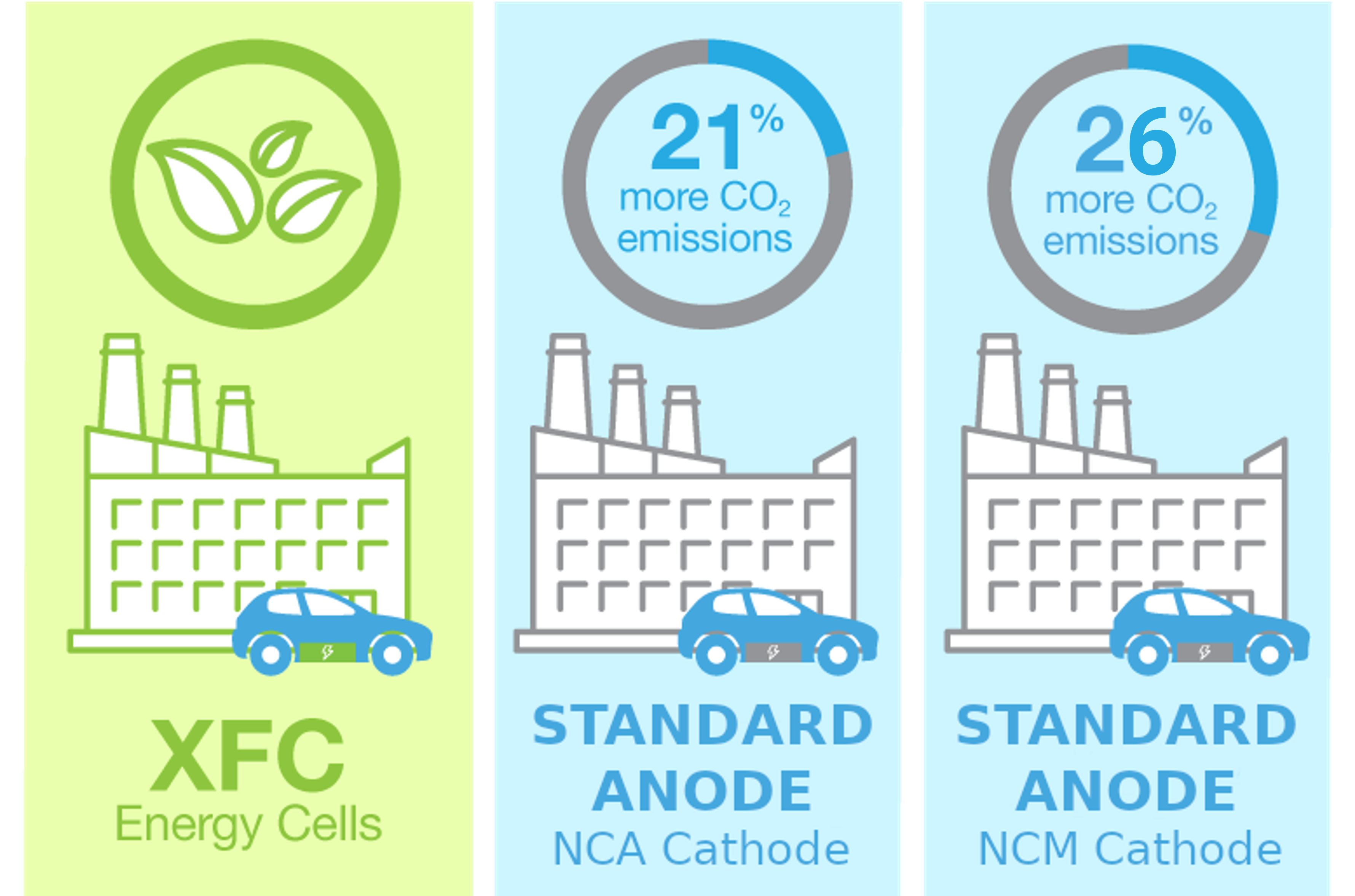

Up to 26% Reduction of CO2 Emissions During Manufacturing

Enevate’s XFC-Energy® technology aims to deliver a significant reduction of carbon dioxide (CO2) emissions for manufacturing of EV batteries compared to today’s conventional lithium-ion EV batteries—21 percent for NCA and 26 percent for NMC combined with conventional anodes [kg CO2 eq. cradle-to-gate, per 1 KWh cell capacity].

.

“The CO2 emission reduction Enevate’s battery technology offers is a very desirable contribution to Renault’s carbon neutrality aim in Europe by 2040 and worldwide by 2050. It provides another critical milestone to bring this battery technology to sustainable EV production by 2025.”

– Philippe Schulz, VP Advanced Powertrain Engineering, Groupe Renault

We’re Positive About Going Neutral

With an estimated 28 million EVs sold per year by the middle of the decade, the automotive industry’s role in electric vehicle greenhouse gas reduction has become an important one. To illustrate, a 21 percent CO2 reduction during manufacturing from a single 100GWh factory over current lithium-ion EV batteries would deliver the equivalent of…

Data references available here.

Easy Answers to the Tough Questions

Yes, multiple reports show EVs produce fewer life cycle emissions than their internal combustion engine-powered counterparts.

The International Council on Green Transport takes a look at the greenhouse gas

emissions cradle-to-cradle for ICE vehicles vs. EV vehicles and concluded that EV’s are significantly

greener.

The majority of EV emissions are created during vehicle manufacturing, and battery manufacturing is the highest contributor of CO2 emissions for the manufacturing of an EV. Before rolling off the assembly line, an EV will generate more greenhouse gas emissions than its internal combustion engine-powered counterparts. However, once they hit the road, the tables start to turn. The energy generation required to charge a battery produces a fraction of the emissions compared to operating an internal combustion engine-powered vehicle. Depending on a multitude of variables, including vehicle size, type of driving, the source of energy generation, etc., greenhouse gas emissions from building and driving a typical EV compared to a standard internal combustion powered vehicle cars are roughly the same after one to two years of operation. Then the EV pulls ahead. By the time each vehicle hits the 200,000-mile lifespan of a typical car, the comparison isn’t even close.

Enevate is working with various EV and battery manufacturers. Production timelines are scheduled starting summer of 2023.

Stay tuned!

Enevate utilizes a higher energy density material and an innovative, ultra-thin multi-layer design to meet the demanding EV specifications in its large format EV cells. By utilizing Enevate’s next-generation battery technology, EV and battery manufacturers could see up to a 26% reduction of CO2 emissions to manufacture EV batteries.

No. In fact, Enevate’s technology offers up to 9% lower cost per kilowatt-hour at the cell level compared to conventional graphite cells.

No cost changes to accommodate an Enevate anode are required. Overall, battery system cost reductions are available at the system level due to improved regenerative braking energy capture capability made available through the fast charge architecture. In addition, a more extensive cold temp operation range for Enevate anodes can help lessen heating requirements to reduce system-level costs.

Enevate’s battery technology strives to provide EV and battery companies with a process for taking measurable, cost-effective steps toward meeting carbon reduction and carbon neutrality requirements.

Enevate’s partners are building large cell manufacturing pilot lines in the MWh range. As a result, we expect our licensees to be in GWh capacity production levels by 2025.

Enevate has made tremendous progress on the road to carbon neutrality. Along the way, we’ve come up with innovative answers to some of the EV industry’s toughest questions about the battery’s role in reducing CO2 emissions. It’s the quest for a cleaner, more economical EV ecosystem that drives us.

Understand the Impact

Enevate CO2 emissions information in accordance with international standards ISO 14044:2006, section 6.1. Further information available from Enevate Corporation.