XFC-Energy® Technology

The Fast Track from Ideas to Innovation

With our unique business model and agile technology development, Enevate can go from ideas to results much more quickly than large companies. Enabled by fast research processes and accelerated electrode and cell-build capabilities, we’re able to innovate up to three times as fast as larger, slower companies.

Enevate has grabbed the attention of the automotive industry moving towards electrification at an accelerated rate. Our technology development team has done the impossible by coming up with a cell technology that combines fast charge, long range, and low-temperature performance.

Our world-class scientists and engineers have accomplished this breakthrough leveraging knowledge of battery chemistry and a broad set of tools we have invested in here at Enevate. Please contact us for further details regarding Enevate’s services including research, development, and implementation of technology relating to fast-charging batteries.

Charge Faster, Go Farther with XFC-Energy® Technology

Electric vehicle customers today essentially have a choice of acceptable range with slower charging, or faster charging EVs with lower range and high cost. Both choices are compromised. With Enevate’s XFC-Energy® Technology, you don’t have to compromise. You get fast charge and longer range.

Enevate technology is built on a three-pillar foundation:

-

- 1. Pure silicon anode

-

- 2. Electrolyte

-

- 3. Cell design

Enevate uses an innovative, multi-layer design that allows us to safely pack more energy into a single cell, because our XFC-Energy® silicon-dominant anode layer requires a fraction of the space of a graphite anode layer used in a conventional cell. In fact, large-format EV size cells achieve over 1000 Wh/L and 350 Wh/kg energy density.

The pure silicon anode is a key battery component. Our technology optimizes the Enevate anode performance through a combination of electrolyte formulation, cell design, and cell formation.

Enevate technology outshines other solutions with optimized cell designs that deliver significantly faster charging and longer vehicle range. Enevate has cracked the code: conventional Li-ion batteries can’t match this kind of scientific innovation.

What We License

We license a comprehensive patent portfolio with more than 650+ patents issued and in-process.

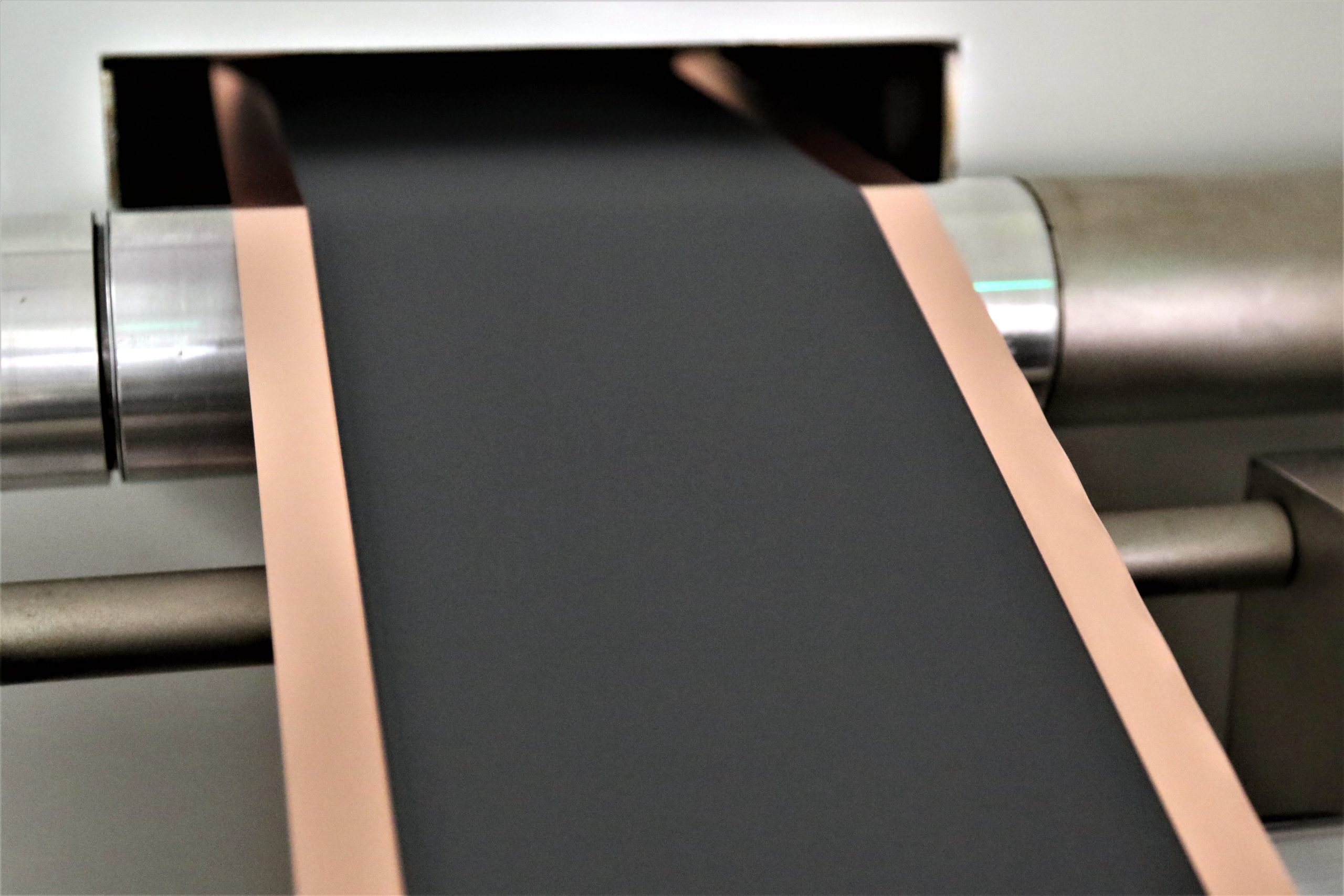

XFC-EnergyTM Anode

Enevate’s anode active materials use significantly more than 70% pure elemental silicon. The self-standing and monolithic anodes are binder-free and porous. Our anodes have more capacity than Li-ion cells found in today’s electric vehicles (EVs). Enevate’s silicon-dominant anode material has about 3,000 mAh/g available specific capacity. This is almost an order of magnitude higher than a conventional graphite cell used in today’s EVs.

Enevate’s cell designs partially utilize the anode capacity to 1000-2000 mAh/g to achieve superior performance. High initial Coulombic efficiencies have been demonstrated, 93% for Enevate’s silicon anode, and 90% for full Li-ion cells. Coulombic efficiencies during cycling are similar to conventional graphite cells.

Lower Material Costs

Batteries with Enevate technology enable material costs lower than conventional lithium ion batteries.

eBoost® Feature for Reserved Energy

When urgently needed, you can utilize the eBoost feature in one of our batteries, allowing you to tap into extra energy beyond what’s available in daily battery cycling. In other words, in rare situations when the battery gauge is near empty, eBoost gives you an extra reserve of battery capacity for additional driving range.

Ready to Power Future Electric Vehicles

Enevate technology has matured and is now in a phase that includes commercialization and industrialization for large-format EV cells. To demonstrate our technology, Enevate has sampled and validated cells for more than 20 global EV battery makers and automotive OEMs.

Cells with Enevate technology can be manufactured cost-effectively in high-volume battery gigafactories capable of supporting the needs of the EV market.